Description

What is the main advantage of waterjet cutting?

Waterjet cutting technology has two equally valuable advantages that distinguish it from other machining techniques – it is versatility and the absence of working area heating.

Versatility

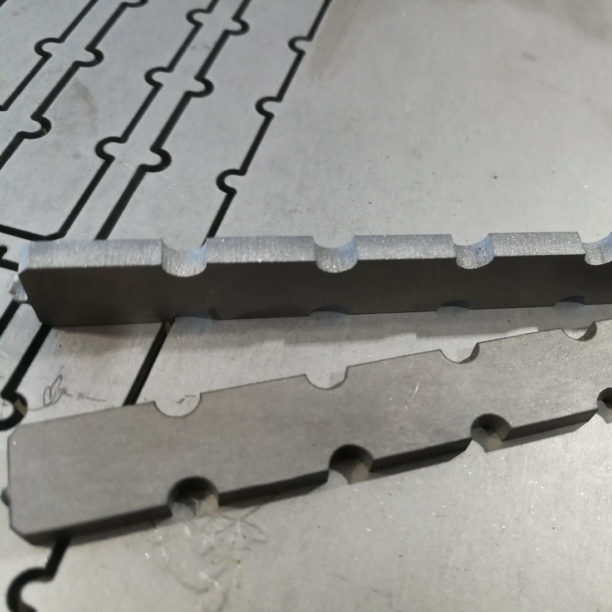

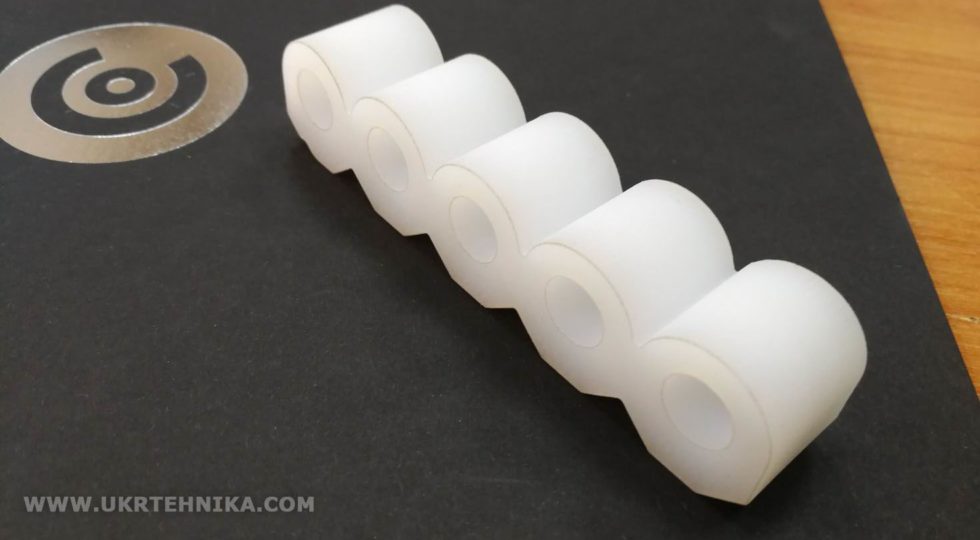

Flow Mach 500 waterjet cutting system of UKRTEHNIKA company makes it easy to cut various materials: metal, stone, plastic, glass, ceramics and much more. Moreover, simultaneous cutting of materials of different thickness up to 250 mm is possible.

No heating of the working area

Waterjet cutting is a cold cutting process. Heating can have a negative effect, which changes the structure and properties of metal alloys. Watercutting is a high-speed grinding of the material, which does not affect its structure and allows you to simultaneously cut several layers.

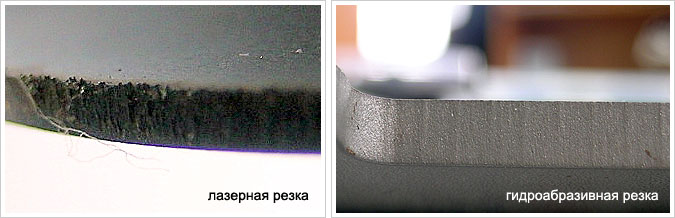

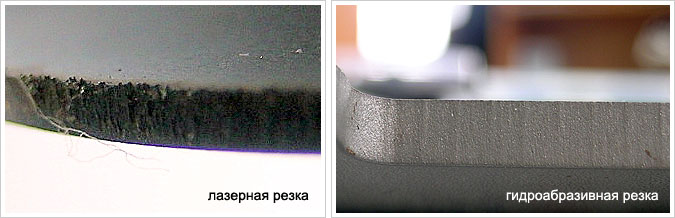

The edges of the details after waterjet cutting do not have hardened areas, flashes, scales, reflows, which will significantly lessen the technological time of processing and significantly reduce the wear of expensive cutting tools.

There is an example of slices with a laser and a waterjet cutter

The main differences between the existing equipment of thermal and non-thermal metal cutting:

- Work with various materials;

- Smoother cut edge;

- No thermal effect on the cutting edge of the material;

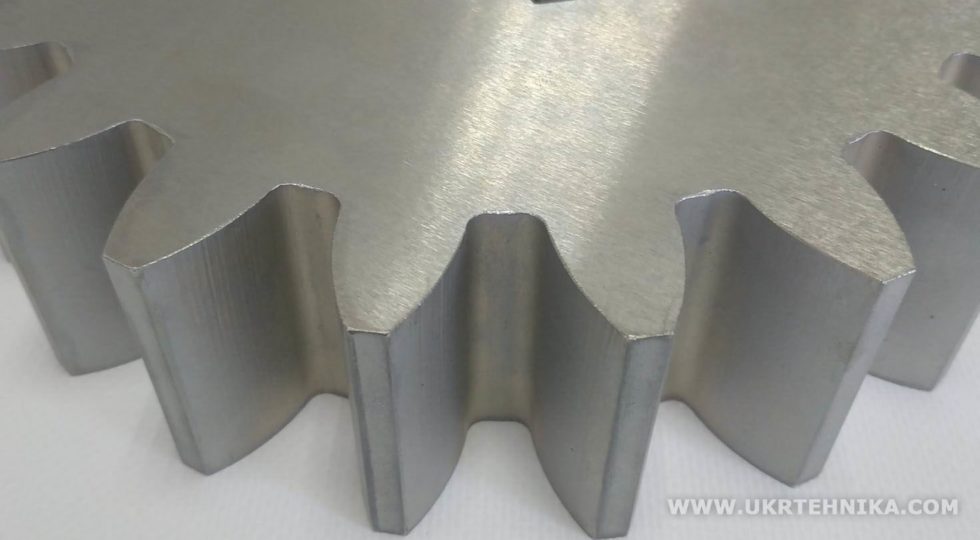

- Ability to cut the most difficult contours;

- High cutting accuracy, superior plasma, laser, gas, mechanical types of cuts;

- Practical wasteless and cost-effectiveness;

- Ability to work with refractory, high-strength, viscous and transparent materials;

- Minimum mechanical effects on the workpiece;

- Allows you to get finished parts.

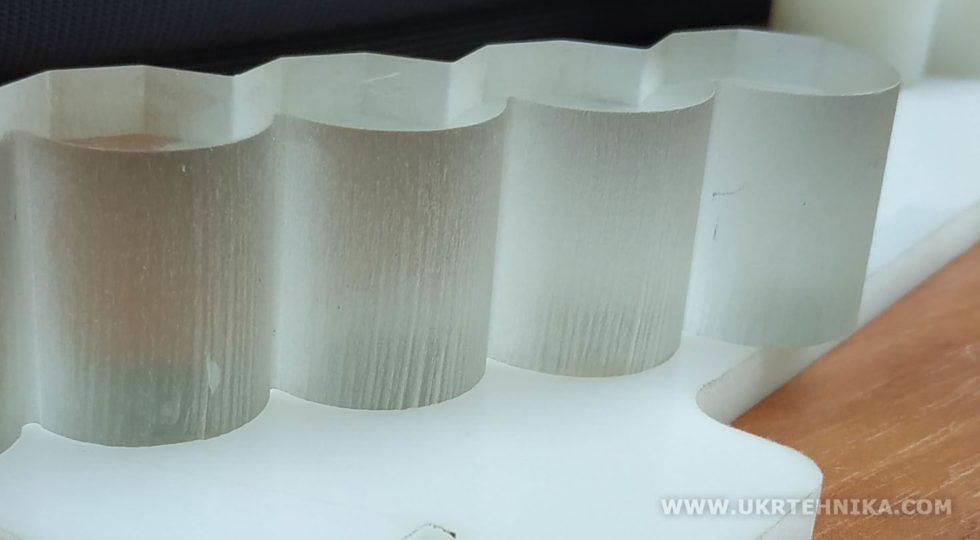

Dependence of the quality (roughness) of the cut on the cutting speed

We use the Flow Mach 500 with its modern architecture and ultra-high pressure technology is unmatched in speed or accuracy.

PRICE

Exact calculation of cost of the order with all features (sizes, quantity of products, optimality of cutting etc.) can be executed only in the special FLOW program. Calculation is carried out by our engineers on the basis of processing of your specification, i.e. CAD format drawing (.DXF is desirable).

The price is operating time of the waterjet. The price depends on: