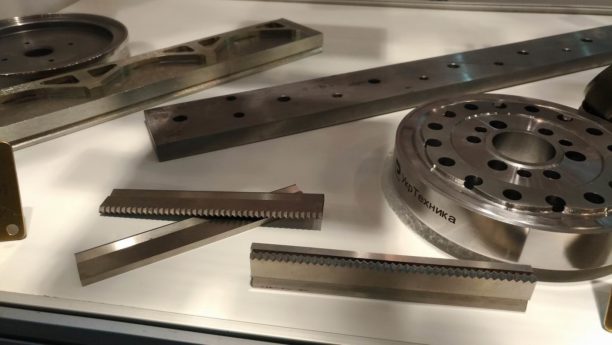

Machining: all types of actions

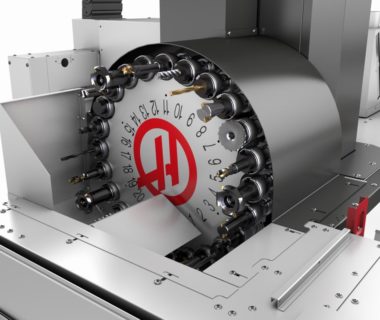

We perform metal machining services by professionals on professional equipment.

High quality is achieved due to the availability of advanced equipment with CNC, its own design office, quality control at each stage of production. The most flexible approach to service and reasonable pricing can create optimal conditions for cooperation. The main priority in the production is the manufacture of technologically complex parts.

We provide: